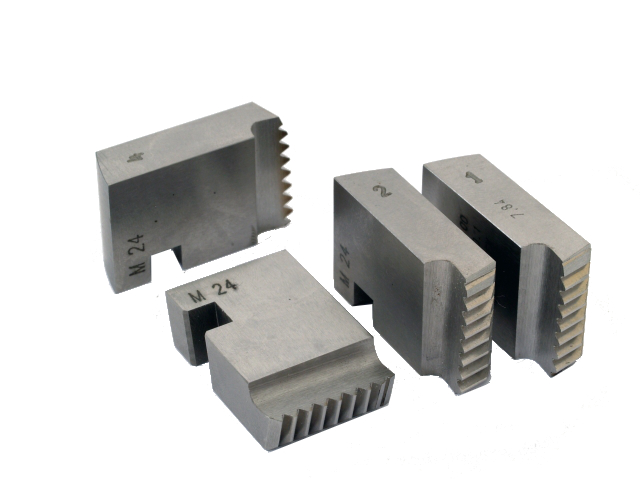

All components are made of quick-cutting material, nitrided. As a result, the rolling head has a very long service life compared to the competitive systems.

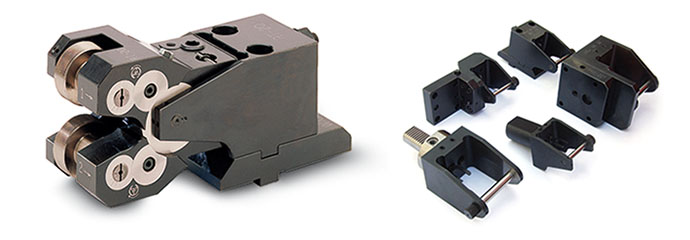

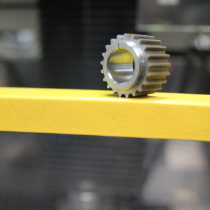

Our axial rolling systems are usable on all common machine tools such as CNC centers, manual machine tools and, if required, on jig boring machines.

Setup on the machine tool is quick, easy and flexible for all tasks. The quality of the threads you produce as well as the durability of our rolling systems and their rollers are the best reasons to choose thread and profile rolling systems over cutting tools.

Machine tool setup and downtime are kept to a minimum. The production process goes through short cycles.

We optionally offer locking mechanisms for many of our rolling systems that can further reduce cycle times and create the fastest and most convenient setup.

Read more: AXIAL ROLLING SYSTEMS

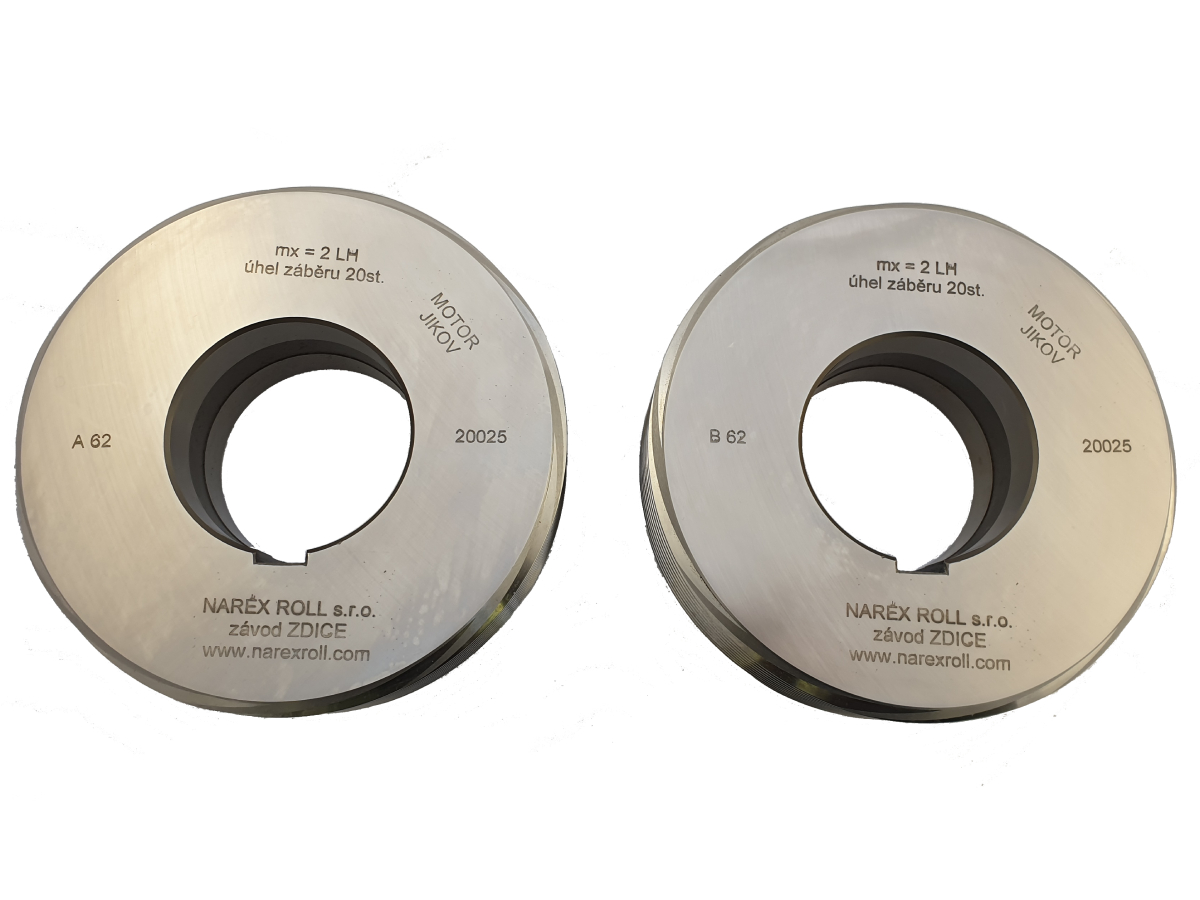

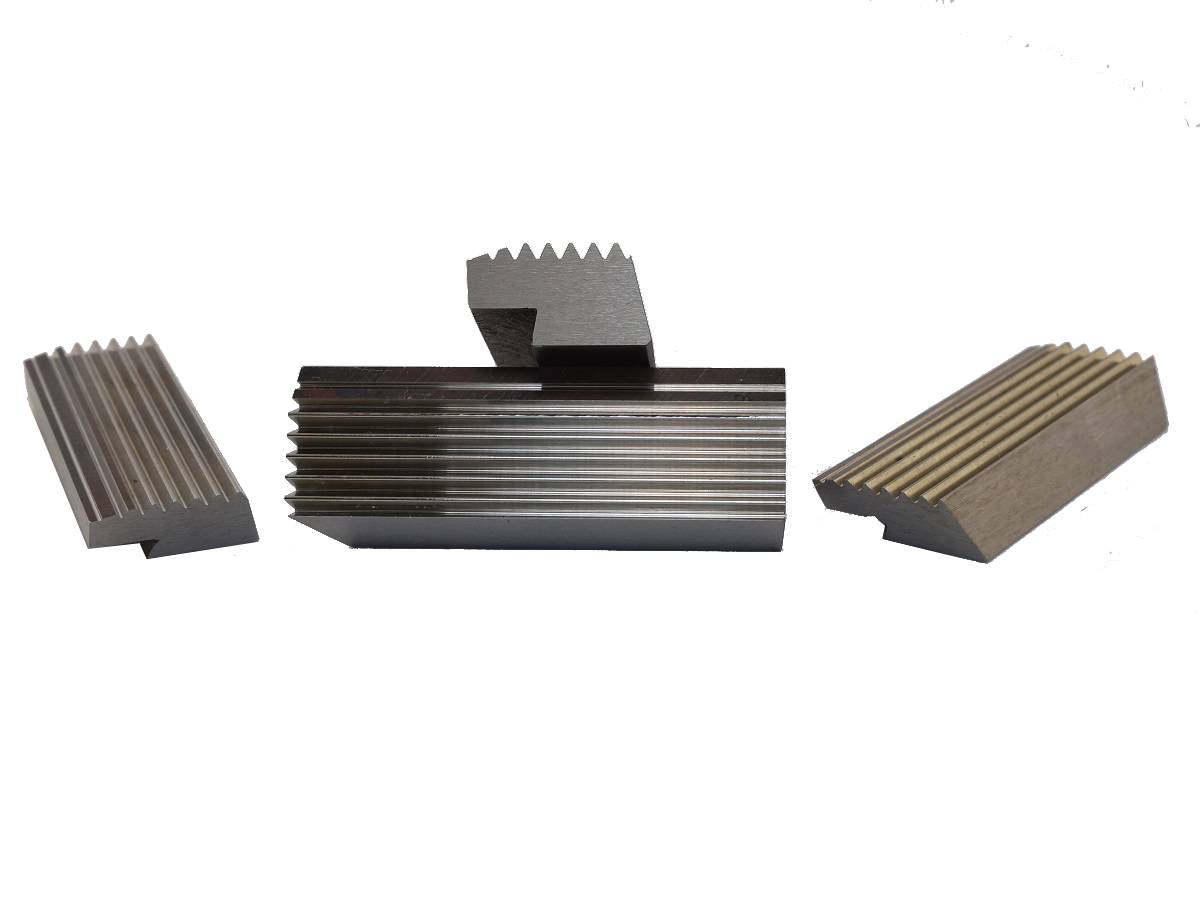

All components are made of quick-cutting material, nitrided. As a result, the rolling head has a very long service life compared to the competitive systems.

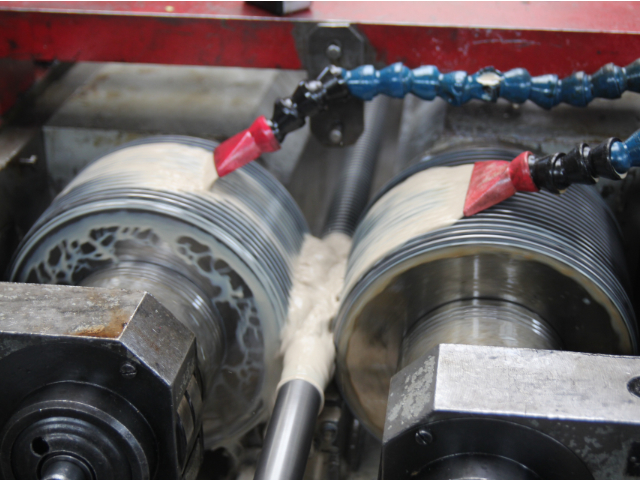

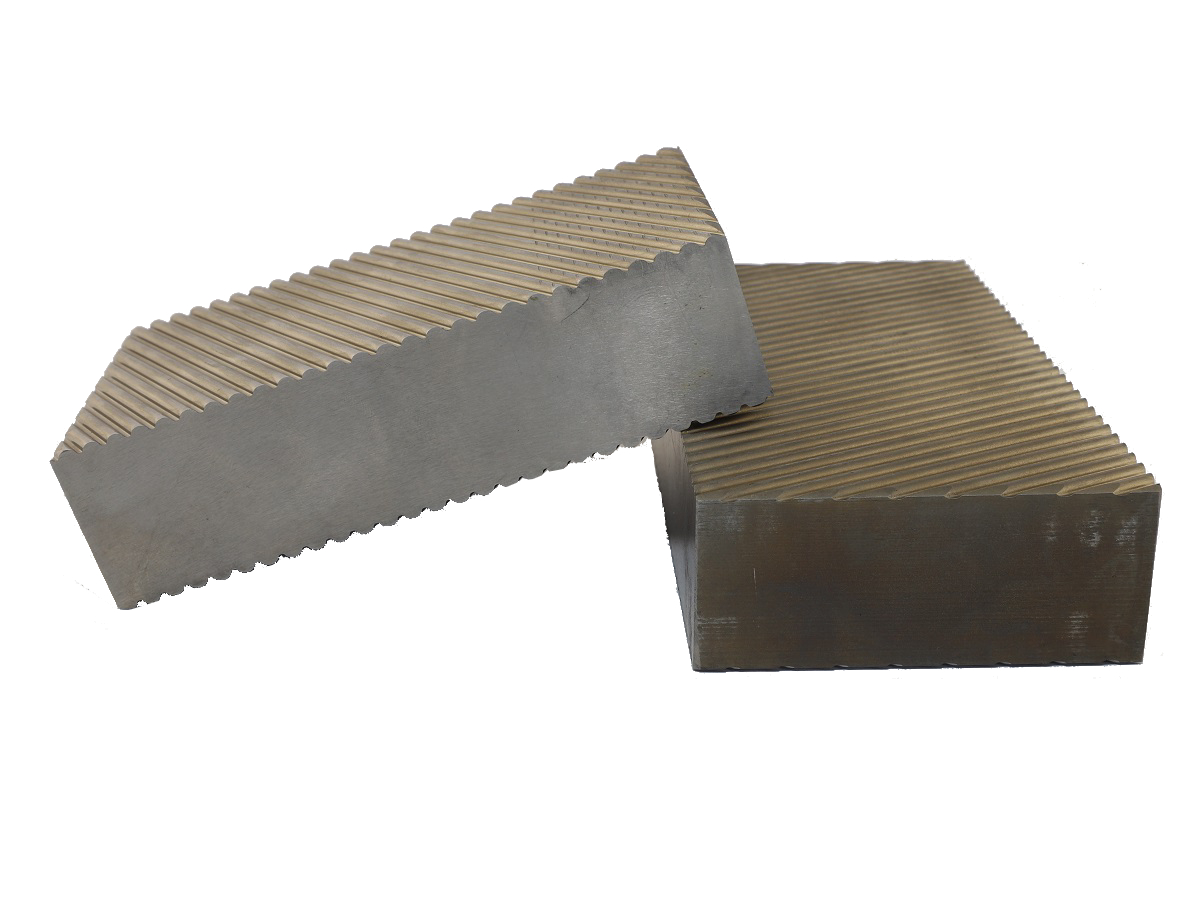

Our tangential rolling systems increase the efficiency of thread and blank production in machining centers, on CNC milling and turning machines as well as on manual cross feed machines.

The main advantage of our tangential thread rolling systems is the ability to roll threads and runners in the workpiece between arms and different diameters, while rolling the shortest threads and runners. Combine these advantages with ultra-fast cycle times. The capacity of your machine tools will increase and you will never want to do without our tangential rolling systems again.

For each of our tangential rolling systems we supply an individually adapted tangential rolling head holder. With this holder, the Gradex tangential rolling head is attached to your machine tool.

Read more: TANGENCIAL ROLLING SYSTEMS